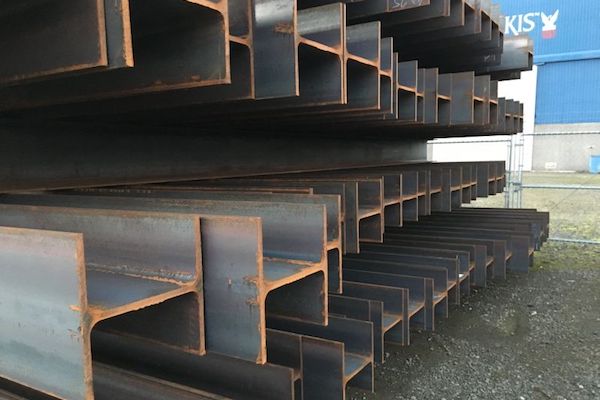

H-shaped piles are commonly used in construction projects for their strength and load-bearing capacity. However, like all steel structures, they are susceptible to corrosion, which can compromise their integrity over time. Protecting H-shaped piles from corrosion is essential to ensure the longevity and safety of the structures they support. Stealth Pipe and Steel pieux en h offers several methods to protect these piles from the damaging effects of corrosion.

1. Galvanization

Galvanization is one of the most effective methods for protecting H-shaped piles from corrosion. This process involves coating the steel with a layer of zinc, which acts as a barrier to prevent moisture and oxygen from reaching the underlying metal. The zinc layer also provides cathodic protection, meaning it will corrode in place of the steel if the coating is damaged. Stealth Pipe and Steel offers galvanized H piles that are well-suited for environments where corrosion is a significant concern, such as coastal or industrial areas.

2. Cathodic Protection

Cathodic protection is another method used to prevent corrosion in steel piles. This technique involves attaching a sacrificial anode, usually made of zinc or magnesium, to the H-shaped pile. The anode corrodes instead of the steel, protecting the pile from rust and degradation. This method is particularly effective in environments where the piles are exposed to aggressive conditions, such as seawater or soil with high acidity. Cathodic protection is a common choice for protecting pieux en h in marine and underground applications.

3. Coatings and Sealants

Applying protective coatings and sealants is a straightforward and cost-effective way to protect H-shaped piles from corrosion. Epoxy coatings, for example, provide a durable barrier that resists moisture and chemical exposure. Bituminous coatings are another option, offering excellent protection in underground and submerged conditions. These coatings can be applied directly to the surface of the piles, creating a protective layer that prevents corrosion from taking hold. Stealth Pipe and Steel provides a range of coating options tailored to the specific needs of different projects.

4. Regular Maintenance and Inspection

Regular maintenance and inspection are crucial for the long-term protection of H-shaped piles. Even the best protective measures can degrade over time, so it’s important to regularly inspect the piles for signs of corrosion or damage. If any issues are detected, they should be addressed promptly to prevent further deterioration. Maintenance might involve reapplying coatings, replacing sacrificial anodes, or repairing damaged areas. Stealth Pipe and Steel offers guidance on maintenance practices to ensure the continued protection of their H-shaped piles.

5. Environmental Considerations

The environment in which H-shaped piles are used plays a significant role in their susceptibility to corrosion. In corrosive environments, such as those with high humidity, saltwater, or industrial pollutants, additional protective measures may be necessary. For example, using corrosion-resistant alloys or increasing the thickness of protective coatings can provide extra protection. Stealth Pipe and Steel works with clients to assess environmental factors and recommend appropriate corrosion protection strategies.

Conclusion

Protecting H-shaped piles from corrosion is essential for ensuring their long-term performance and safety. By employing methods such as galvanization, cathodic protection, protective coatings, and regular maintenance, Stealth Pipe and Steel pieux en h can significantly extend the lifespan of these critical structural components. Understanding and implementing these protection methods is key to maintaining the integrity of construction projects that rely on H-shaped piles.