For any manufacturing industry, a warehouse serves as one of the most important functions. It consists of a few individuals who operate many numbers of warehouse equipment, which are certain machinery or tools used in various processing areas.

The right selection of equipment may help any warehouse to make it an efficient warehouse. A pallet inverter is one of the pieces of equipment that can raise the bar of any warehouse performance. Top Industries, a well-known material handling equipment supplier can offer you a customised solution for your pallet inverters.

Importance of warehouse equipment

Choosing the right variety of warehouse equipment will not only increase the performance of any warehouse but also reduce the risks of accidents or personal injuries to the people working in the warehouse.

You may have the best manpower in your warehouse, but unless you have installed the right kind of equipment, you cannot achieve your target that is needed in a modern-day industrial environment.

Some of the important warehouse machinery and equipment are as follows:

- Bumpers

- Conveyors

- Doors

- Forklifts

- Levellers

- Lights

- Pallet inverters

- Pallet jacks

- Ramps

- Seals

- Shelters

- Storage racks

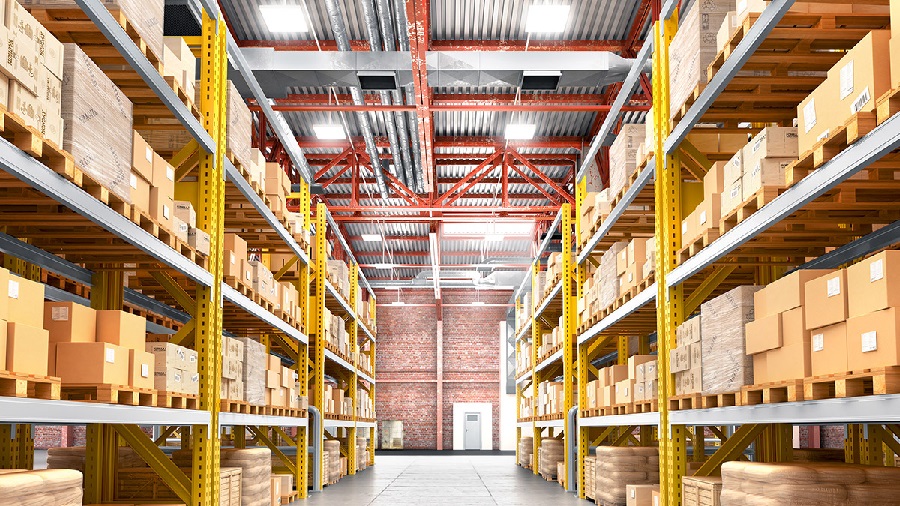

Storage

Another important area of operation of any warehouse is the storage area which is normally in bulk or stored in a rack. The bulk storage pallets are simply put on the warehouse floor and all rack storage pallets are stacked within racks so that the vertical ceiling space can be utilised.

A few usual rack warehouse storage equipments are as follows:

- Pallet racks

- Cantilevered racks

- Wire decking

- Reel racks

- Heavy-duty shelving

A few top quality storage systems can be as follows:

- Push back racking

- Drive-in racking

- Pallet flow racking

Occasionally, any high-density systems are able to maximize the proper use of the available space up to the point where any extra storage facilities may not be needed.

FIFO (first-in, first-out) inventory systems will influence whether such high-density systems will be appropriate for the warehouse.

An area called NA (Narrow Aisle) or VNA (Very Narrow Aisle) area is a certain type of aisle that can restrict lift movement. Any typical counterbalanced lift truck will need a minimum of 11 feet of aisle-width space to turn around.

Because of its enhanced ability to manoeuvre through confined passages, certain 3-wheel pallet jacks can commonly be used in warehouses.

Handling and transfer

For moving materials throughout a warehouse, the following equipment will be needed:

- Hand trucks

- Pallet jacks

- Scissor lifts

- Stackers

- Lift trucks

- Lifts

There are unique designs, like narrow-aisle forklifts, available for high-density storage plans. Reach trucks that are guided by wire or rail are sometimes employed in warehouses with small aisles to maximise storage capacity.

AS&R, also known as automated storage and retrieval, can reduce the need for labour, but at a price. Such systems commonly use vertical or horizontal carousels meant for stock storage. Paper rolls and storage barrels are two examples of unpalletized commodities that can be handled with specialised forklift attachments.

Conveyor systems of many kinds are utilised in some warehouses to move chosen items. Conveyors using skate wheels, live rollers, and gravity are all often used. Sometimes, temporary and flexible conveyors are used as well.

Many more warehouse equipment are developed by Top Industries and to remain updated you can follow on Twitter account of the company.