Operating a powder coating firm for industrial components and materials might be profitable, considering that this market has been growing year after year due to increased demand.

Powder coating is a coating procedure in which a finely ground resin and pigment mixture is sprayed electrostatically onto a material’s surface. Powder-coated materials usually have a consistent, high-quality, and appealing finish. These materials generally last longer than their counterparts that have not been powder coated—business owners who perform this kind of coating benefit from the entire powder coating process.

This guide will show you the equipment that you need to buy before you start this business.

Equipment for Spraying

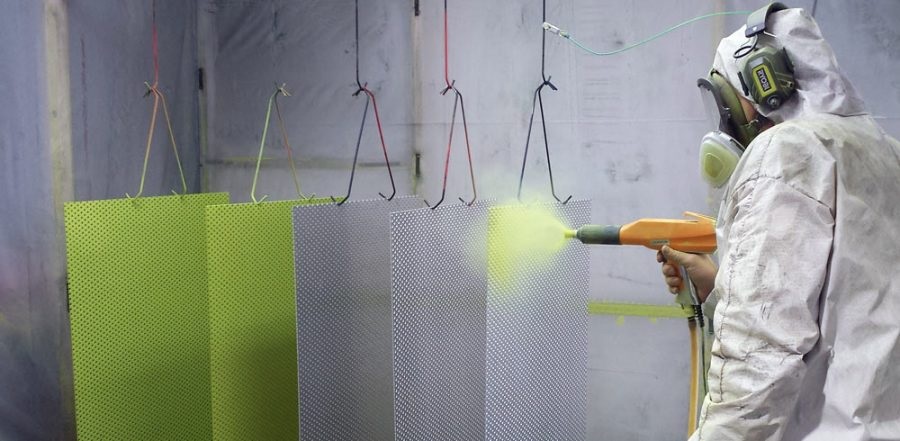

Because you’ll be working in the powder coating sector, you’ll need spraying equipment that can handle the load of parts you’ll be producing. The most important equipment for spraying is the powder spray gun. The objective of the powder coating gun is to electrically charge the powder and send it towards the components you are powder coating.

The amount of charge applied to the powder is indicated in kilovolts (kV). Your spraying equipment should also include a booth in which the items will be coated as well as spray guns to accomplish the powder spraying process. In line with the authorities’ rules, this equipment must have enough exhaust ducts and ventilation.

A Curing Oven

Curing powder coatings necessitates the use of ovens. Powder-coating ovens should be capable of maintaining temperatures of 450°F. Solvents are not required in powder-coating ovens. Your curing oven, like your spraying equipment, should have the ability to hold the number of components you plan to powder coat.

The oven should have heating coils to direct heat to the whole object in convection heating. Convection heating permits heat to travel towards a component without requiring direct contact; the heating coils do not come into contact with the coated object and hence do not affect it. If you’re going to make a few little pieces, a lot smaller oven can be everything you require.

Powder coating automobile bodywork or huge parts, on the contrary, would necessitate a bigger oven, such as a walk-in oven. You must have a container filled with a solvent that will be used to clean parts, irrespective of the curing oven’s size. You must also clear up a drying space where you may hang freshly cured components.

Materials for Powder Coating

After you have bought the spraying apparatus and the curing oven, you’ll need to find the right powder coating colors and other components. Remember that blending pigments is rarely done unless the colors are black, grey, cream, or white tones. So, if your client requests a customized shade, you must purchase and select the appropriate color for the project. Solvents for cleaning, masking equipment for concealing bare parts, and paint removers are also required.

As we have seen above, there is various equipment required in powder coating. It is advisable to consult a reputable Powder Coating Equipment Company in order to choose the best equipment for your business. Getting these kinds of equipment, the right location, and the necessary permits and licenses will make it much easier to start and grow your business in powder coating.